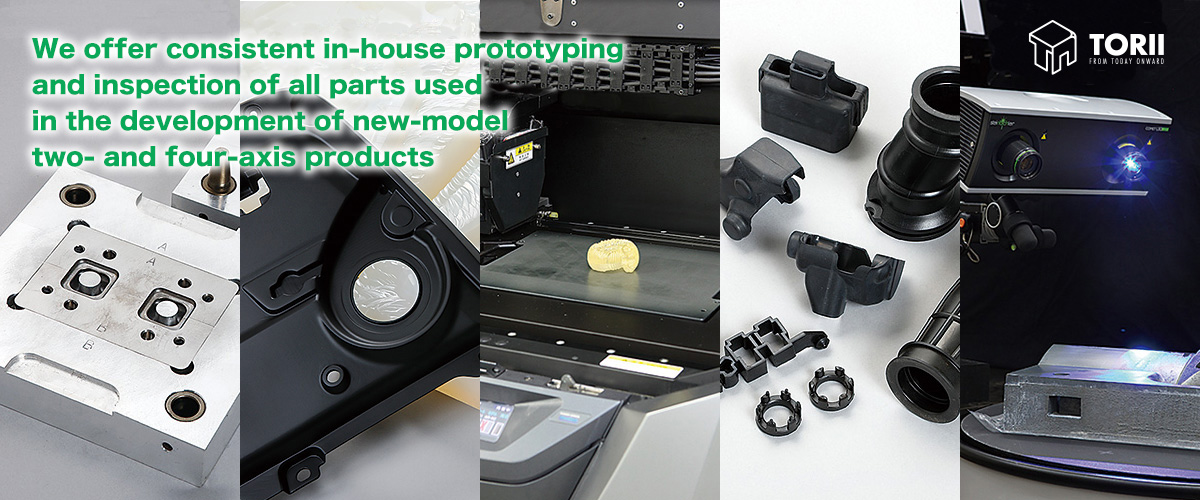

Prototyping and validation towards mass production account for a large share of development work for new two-wheeled and four-wheeled vehicle models. In the prototyping processes that accompany our customers’ development of new products, we earn their respect by utilizing one-stop production to respond to their needs quickly, and by leveraging our accumulated expertise to offer proposals appropriate to their requirements. We have adopted the motto of “Make even better things tomorrow than today,” which is reflected in how we strive to polish our skills to meet our customers’ wishes and play our part in the creation of better products.

Torii was founded in 1980. We apply ingenuity and the experience we have accumulated to support the creation of precise, accurate products.

We find pride and joy in finishing each product item conscientiously and contributing to the creation of better products.

We leverage in-house production to achieve shorter delivery times with reduced costs. Working in close liaison with our partner companies, we to provide a smooth, trouble-free response to a broad range of requests.

Decide matters such as product specifications and machining methods.

We respond flexibly to budgets and delivery times.

We can also accommodate orders for design based on non-contact measurement.

Fabrication is based on our own in-house production.

Our finishing and inspection processes are careful and thorough.

We deliver your products without fail.

We take orders for as little as one item, whether it is large or small, plastic or metal.

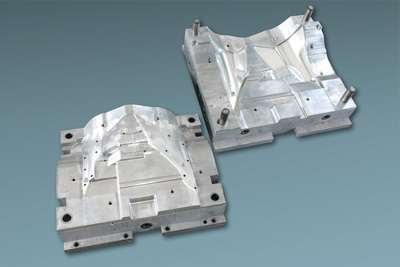

We fabricate molds to suit the required prototyping content, such as injection molding, rubber molding, and sheet metal pressing, to create prototypes with the same properties and materials as the mass production items.

We can mold products ranging from small items up to large items such as car bumpers, offering short delivery times and low prices.

This method is suitable for low-cost fabrication of prototypes where rapid delivery times are required.

We use silicon molds and apply our wealth of skills and experience to cast even complex shapes.

We handle all stages in-house, from data design through to die machining and molding.

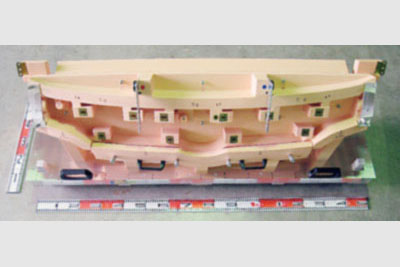

We have a strong reputation for fabrication of the inspection jigs used in mass production.

We fabricate inspection jigs to match your requirements, adapted to your inspection schemes and usage methods

With many years of experience and the latest equipment, we can provide high-precision, non-contact 3D shape measurement of items ranging from small workpieces to large subjects such as real-sized pleasure boats. We also provide on-site measurement.

We make use of CAD/CAM extensively to generate the data optimized for fast and precise machining. We also apply the CAD skills we have acquired over many years to support reverse engineering.

A world where beauty of a finish relies on the artisan's skill

We hone our skills daily in the quest to craft products that combine aesthetic design with functionality.

We fabricate the hard models that are indispensable for validating the design of new models of products.

We recreate designs accurately, adapting to the materials required.

| Trade name | Torii Corporation |

|---|---|

| Headquarters |

Okubo 418-15, Iwata, Shizuoka Tel.: 0538-38-4111 Fax.: 0538-38-4113 Website address: http://www.ktorii.co.jp/ E-mail address: kt@ktorii.co.jp |

| Representative | Toshitada Torii |

| Nominal capital | JPY10 million |

| Founded | January 6, 1980 |

| Business content |

|

| No. of employees | 14 (12 male, 2 female) |

| Average age of employees | 39 |

| January 1980 | Founded in Aioicho, Naka-ku, Hamamatsu by Toshitada Torii, the current representative |

|---|---|

| June 1986 | Relocated factory to Kamo, Iwata City |

| June 1991 | Established Torii Pattern Limited (headquarters: Mukojuku, Naka-ku, Hamamatsu) |

| May 1996 |

Built a new factory in Okubo, Iwata City, and relocated. Introduced CAD/CAM and a machining center |

| June 1997 | Changed to a joint-stock company, and changed name to Torii Corporation |

| February 2002 | Expanded the factory |

| June 2014 | Relocated headquarters registration to Okubo, Iwata City |

| June 2016 | Built a new company building and factory on land adjacent to the existing factory |

| October 2017 | Installed EC650SX-61A injection molder |